Testing Center

Setting a new global standard in product testing and quality control.

- Home

- Testing Center

BIKI’s Dedication to Quality Control

Strict implementation of quality control and product testing reflects our commitment to provide your customers with exceptional shoe care and maintenance solutions. We accomplish this through a seamless combination of adherence to routine inspections, automated production lines, and a flexible production process, capped by intensive testing.

1,000 Products,

1,000 Standards

The intricacy and sophistication of our products require specific procedures for each to attain perfect production. As such, we formulate a standard process that sets the criteria on how we create them, ensuring we pay close attention to every detail.

And with over a thousand products listed, we also have more than a thousand production standards in place.

Thorough Inspections

01

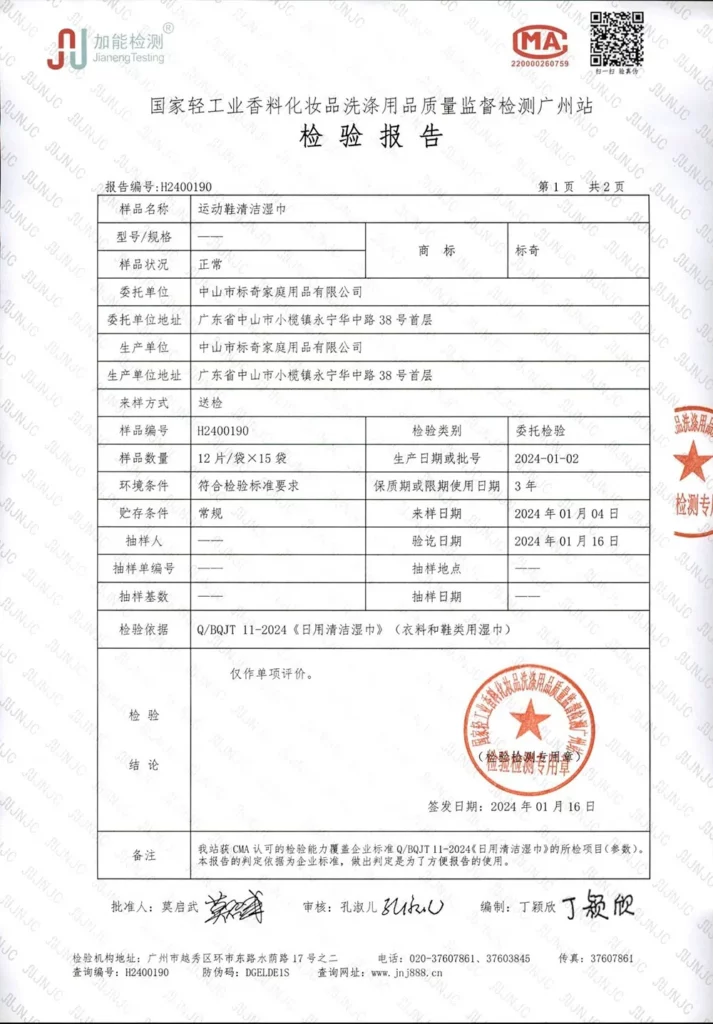

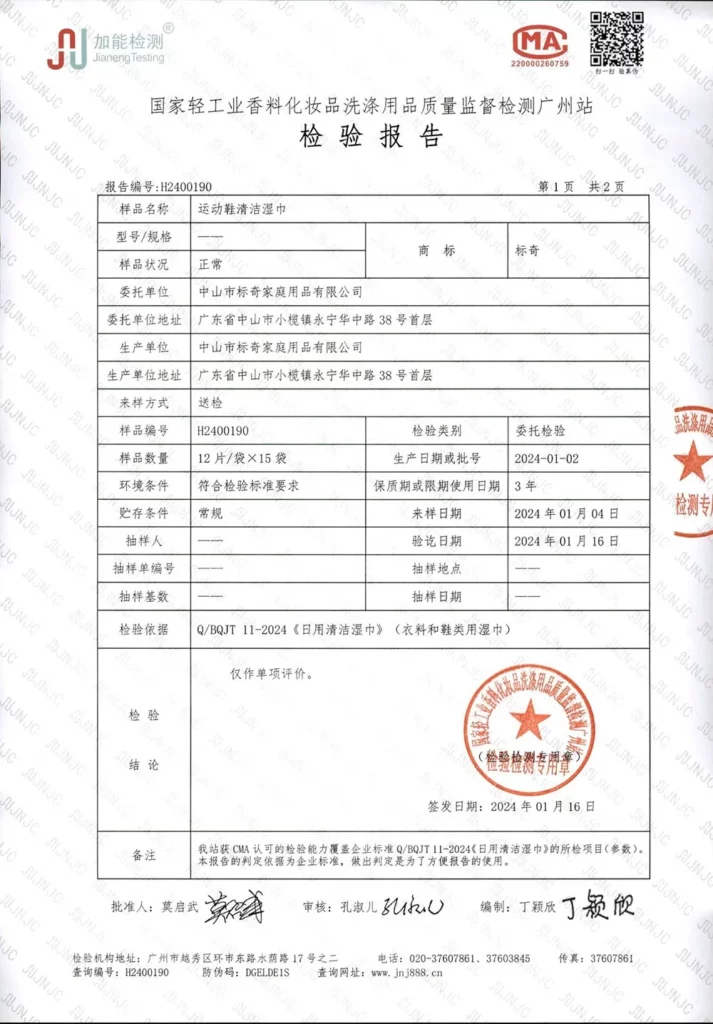

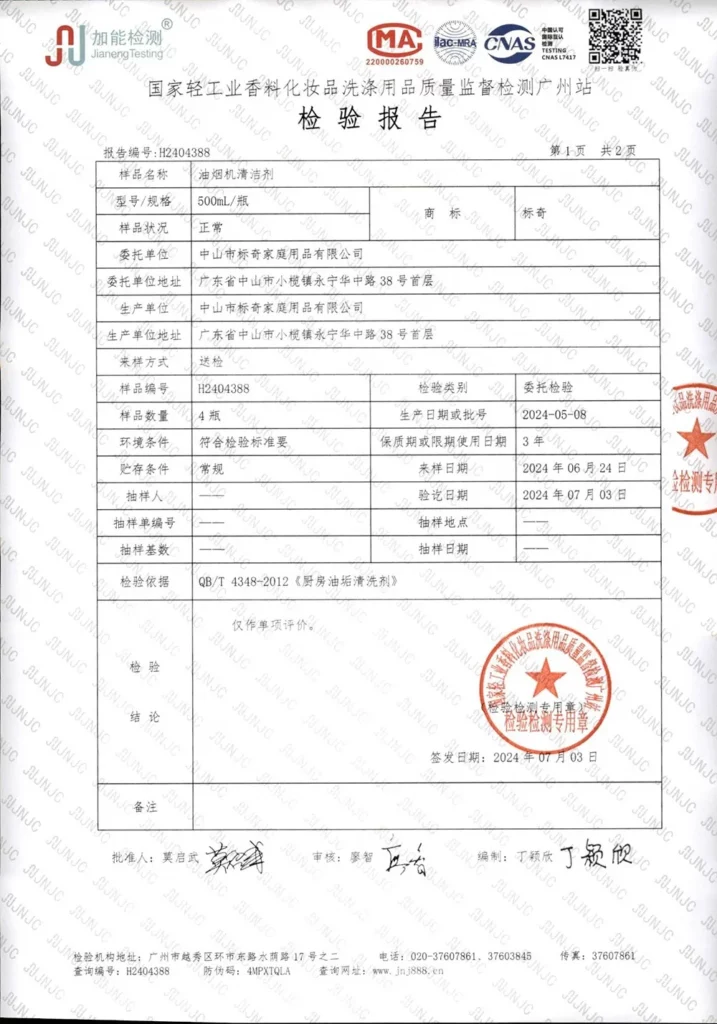

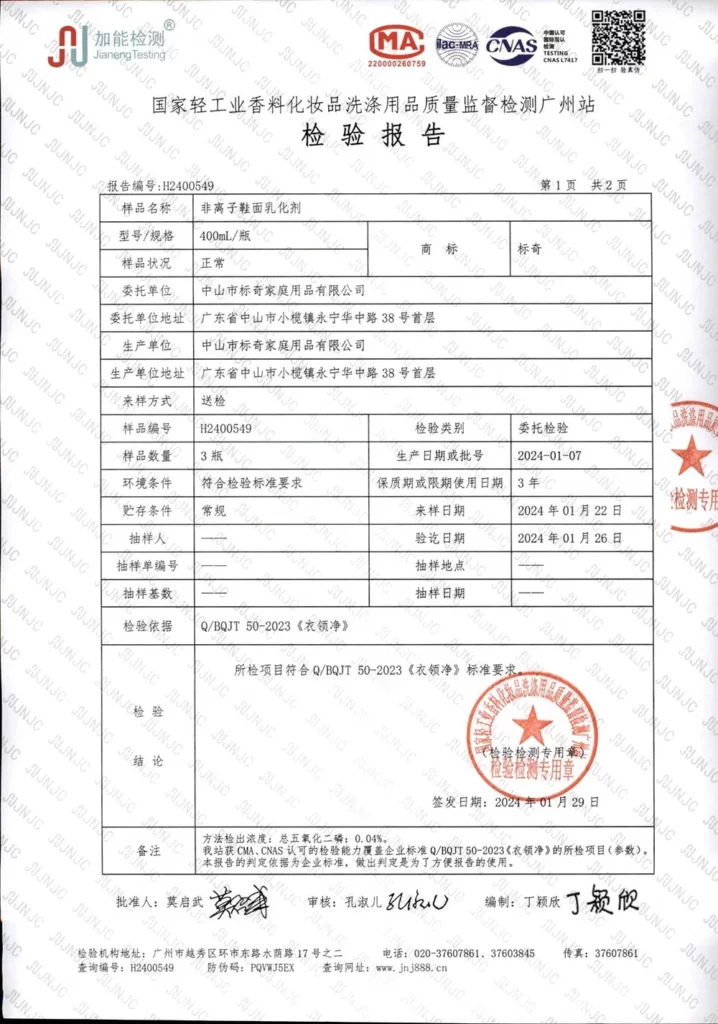

Quality control starts with material procurement

We review the supplier’s test reports and compare samples against our established standards before storing the ingredients. Chemicals, on the other hand, are forwarded to our cutting-edge laboratory for stability and functionality testing. Any material that doesn’t meet our requirements is returned to the supplier.

02

Pre-Production Inspection

After procuring the necessary materials for the product, they go to our laboratory for sampling. Our quality control experts then generate a report which can be referenced per request.

03

Quality Checks During Production

Each batch of shoe care and maintenance products goes through a series of inspections after every production step. Following our standards and customer requirements in the process, we ensure the batch adheres to all metrics while keeping samples for testing.

04

Stamped for Assurance

Before leaving our facility, we check the quality and consistency of the finished products and their packaging, making sure they match what you expect from us. Additionally, we inspect the carton to guarantee that the contents are well-protected during transit. Once everything passes our standards, they’re given to the logistics team for shipping.

Inspection and Sampling

Along with routine quality checks during production, a sample from each production line is taken and reviewed three times. This process helps us maintain the highest benchmarks throughout the process.